Dynamics Simulation

Understand dynamic performance of your designs using these capabilities

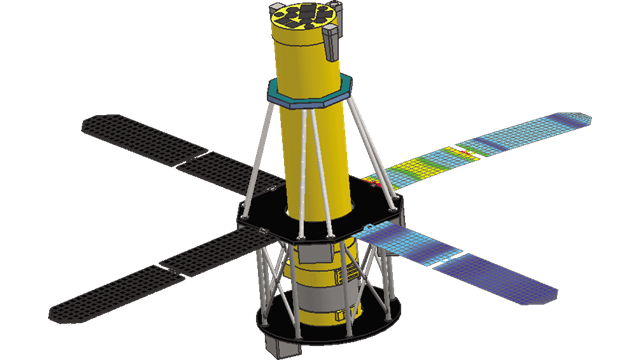

Most machines and vehicles experience vibrations and other excitations that can impact their structural performance. Historically, physical testing methods have been used for understanding the structural dynamics of various products. However, testing is costly and time consuming, and perhaps not very feasible with large structures like aircraft or ships. Simulation has become a key technology in understanding the structural dynamics for automobiles, spacecraft, jet engines, ships, electronic devices and industrial machines.

Simcenter offers a comprehensive solution to understand, analyze and improve the response when a system is subjected to dynamic loading. Simcenter builds on over 50 years of dynamics analysis experience to offer you the ability to efficiently understand and avoid excessive vibrations and stresses. Dedicated capabilities are available for noise, vibration and harshness (NVH) engineering, rotor dynamics and correlation.

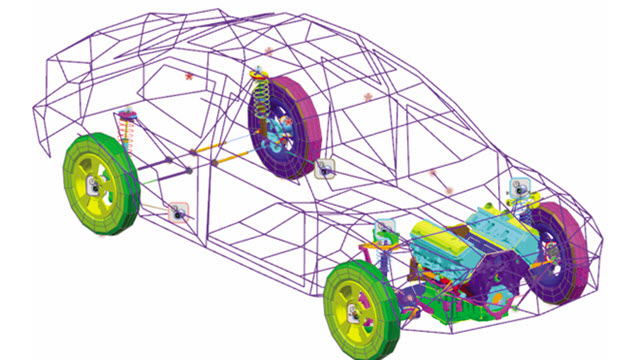

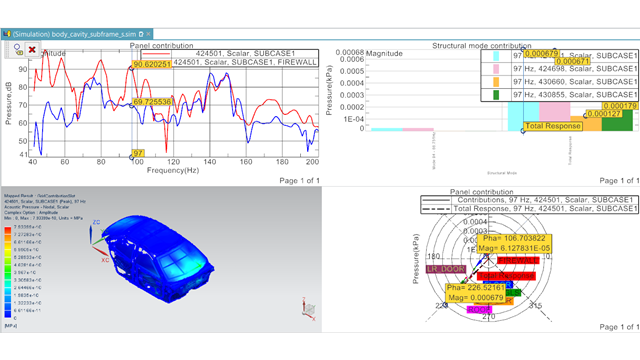

Noise, Vibration & Harshness (NVH)

NVH performance strongly impacts the driving experience and perception of quality for your end customer. Simcenter offers integrated tools and solvers to predict NVH characteristics and analyze the root cause of noise and vibration problems. With Simcenter, you can create full vehicle level FE models for NVH starting from subassembly models, through an interactive network display.

Response Dynamics

Simcenter’s unique response dynamics solution makes dynamic analysis more accessible and efficient. It allows you to predict the forced response of structural systems under various loading conditions in a single, interactive graphical user environment, thereby eliminating the complexity of setting up and launching analysis and providing rapid insight into dynamic behavior. Analysis information can then be used to perform design studies to enhance the new product development process and confirm the quality of designs prior to physical prototyping and production.

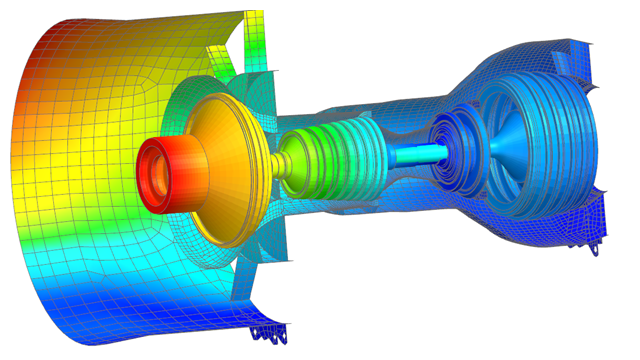

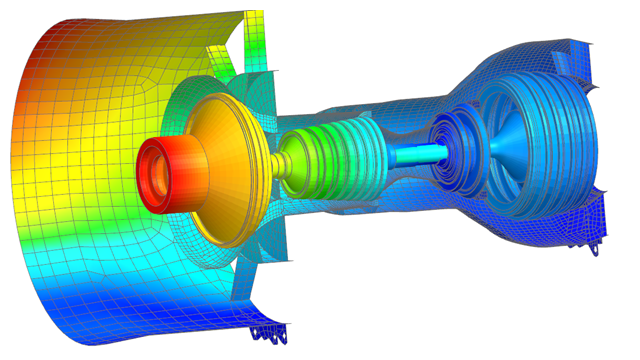

Rotor Dynamics

Rotating systems, like gas turbines, pumps and more, are subject to gyroscopic forces such as coriolis and centrifugal forces that are not present in stationary systems. Simcenter provides the capability to predict the linear dynamic behavior of rotating systems. Users can simulate rotating system loads, perform synchronous and asynchronous analysis to generate Campbell Diagram data, predict whirl frequencies and critical speeds and detect instability in rotating components.

Structural Dynamics

Starting from the product concept phase, analysts and specialists can rely on Simcenter structural dynamics solutions to analyze design decisions and systematically improve dynamic characteristics of the system. Simcenter is fully customizable to suit your dynamic analysis processes by creating predefined templates and streamlining the product engineering process.

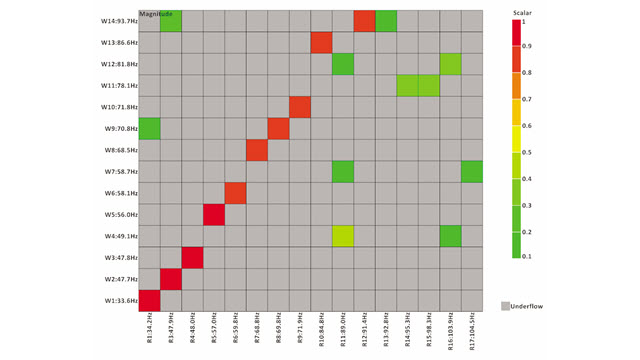

Test-analysis Correlation & Updating

An integral part of making product engineering decisions is having confidence in the simulation models so you can accurately predict reality. Correlation solutions allow you to validate and improve the dynamic behavior of simulation models from physical test data.

Simcenter provides you with the ability to compare and correlate your simulation data with physical test results. You can geometrically align models, pair modes from both solutions, view mode shapes and frequency response functions, and calculate/display correlation metrics.