High Temperature Processes & Heat Transfer

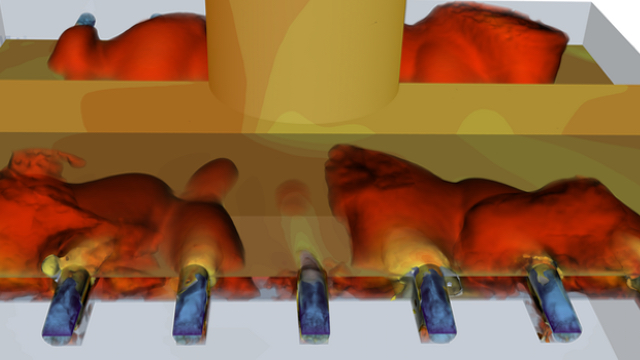

Leverage the power of multi-physics simulation and testing to provide a more thorough understanding allowing for a better burner and furnace designs that meet process and financial performance goals, as well as government regulations.

Thermal process engineers who design or operate high-temperature equipment rely on heat transfer simulation solutions to opportunistically decrease energy costs, achieve process performance targets, reduce waste, and meet pollution regulations. Our solutions provide innovators with tools that can help overcome the challenges of achieving operational excellence in the chemical and process industries by:

- Increasing combustion efficiency with higher heat absorption for a given amount of fuel

- Increasing throughput efficiency by reducing raw material requirements while increasing yields and sustainability, as well as reducing the overall environmental impact

- Increasing yield through higher conversion and selectivity

- Predicting and understanding the real-world behavior of flame dynamics, heat transfer and thermal wear, NOx, soot, CO and other emissions

- Troubleshooting and improving under-performing processes or equipment in existing plants

- Using design space exploration tools to identify undesirable process conditions, and find new configurations and operating conditions to optimize process performance