Process Safety

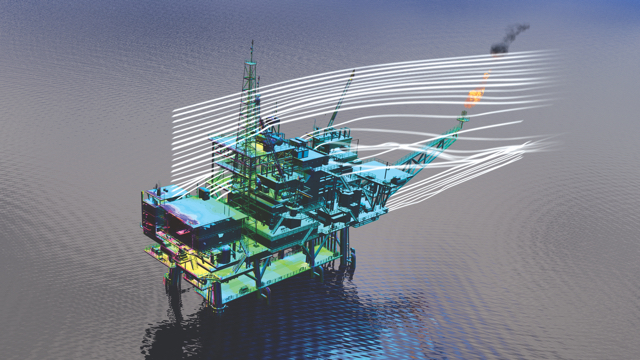

Process safety is critical to all oil and gas production and processing facilities. Through the use of digital twins it is possible to simulate safety related events and to use the results and accompanying data to design and operate your assets with maximum insight in order to minimize process safety risks. Our solutions provide an unparalleled range of capabilities enabling you to simulate the unique behavior and responses of your systems and processes allowing your team to improve safety, maximize efficiency and optimize integrity.

Understanding, quantifying and managing risks to safety is paramount from the initial design to the end of life for a system or facility. Whether you are looking to understand system level behaviors or predict detailed component responses through computer aided engineering techniques, simulation based digital twins can provide the insight and data you need to maximize process safety.

Our solutions provide opportunities to:

- Create digital twins to visualize and understand real world behaviors

- Assess the impact of layout on safety related events and consequences

- Simulate real world behaviors involving flow, heat transfer, structural response and control systems

- Model planned and predict unplanned events, such as gas releases and dispersion

- Manage interactions between your facility and the environment

- Apply design space exploration to identify news methods of increasing process safety

- Manage all of your simulation and analysis data in one place

For engineers who design or operate processes involving the extrusion or mixing of materials with complex rheological characteristics, our modeling and simulation solutions help you understand complex behavior, achieve process performance targets, and optimize operations by:

- Design and test extrusion dies virtually, then simulate the extrusion process with automatic die shape optimization before building expensive prototypes

- Lower engineering and extrusion line costs by evaluating multiple design options faster, assess “what if” strategies, and avoid issues that give rise to faulty out-of-spec products

- Accurately simulate flow in static mixers and reactors, as well as the flow in and out of commercial packaging, such as industrial lubricants and greases

- Minimize material waste and improve operational efficiency by reducing out-of-spec products ensuring consistently high product quality