Complex Rheology

Numerous Energy & Utility industry segments work with processes that include non-Newtonian fluids with complex rheological properties. Our solutions simulate industrial mixing to design and optimize processes such as extrusion, co-extrusion, thermoforming, and static mixing for non-Newtonian materials that have complex rheological characteristics.

For engineers who design or operate processes involving the extrusion or mixing of materials with complex rheological characteristics, our modeling and simulation solutions help you understand complex behavior, achieve process performance targets, and optimize operations by:

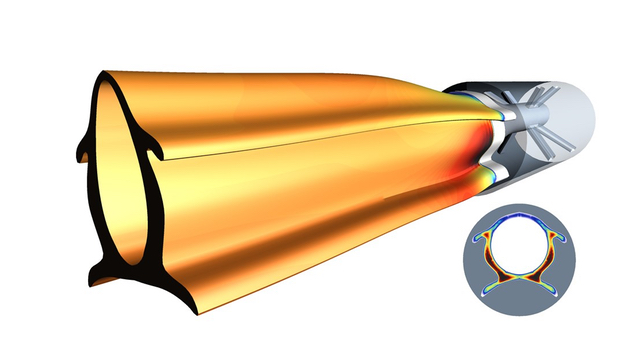

- Design and test extrusion dies virtually, then simulate the extrusion process with automatic die shape optimization before building expensive prototypes

- Lower engineering and extrusion line costs by evaluating multiple design options faster, assess “what if” strategies, and avoid issues that give rise to faulty out-of-spec products

- Accurately simulate flow in static mixers and reactors, as well as the flow in and out of commercial packaging, such as industrial lubricants and greases

- Minimize material waste and improve operational efficiency by reducing out-of-spec products ensuring consistently high product quality