Simcenter 3D

Simcenter 3D is a comprehensive, fully-integrated CAE solution for complex, multidisciplinary product performance engineering. The software delivers revolutionary improvements in simulation efficiency. With advanced 3D modeling capabilities and simulation solvers that cover a comprehensive range of physics, Simcenter 3D helps you gain better insight into your product’s overall performance. This is achieved through a fully integrated and managed, yet open environment, where you perform all CAE pre-and-postprocessing on CAD data from any source for Simcenter and third-party solvers.

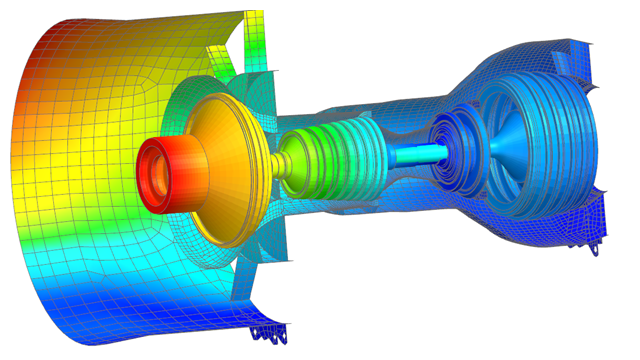

Meshing

Acoustic Simulation

Accurately representing the physical behavior of the different fluid and solid phases is key to capturing the real-world performance of your product. Simcenter offers a variety of both Eulerian and Lagrangian modeling capabilities to suit your simulation needs.

Optimization

Dynamics Simulation

Most machines and vehicles experience vibrations and other excitations that can impact their structural performance. Historically, physical testing methods have been used for understanding the structural dynamics of various products. However, testing is costly and time consuming, and perhaps not very feasible with large structures like aircraft or ships. Simulation has become a key technology in understanding the structural dynamics for automobiles, spacecraft, jet engines, ships, electronic devices and industrial machines.

Simulation Automation & Scalability

As companies increase their reliance on simulation, they are seeking ways to speed-up the analysis process and increase simulation throughput. One way to increase simulation throughput is to capture repetitive CAE processes, standardize them, and then automate them. Simcenter allows you to capture the expertise of senior analysts and make it available for junior engineers in your organization to use in the form of wizards or templates.

Motion Simulation

Understanding the operating environments for intricate mechanical systems – like in wing flaps or landing gear, sliding sunroofs or suspensions, or photocopiers and other mechanisms – can be challenging. Motion simulation calculates the reaction forces, torques, velocities, acceleration and more for mechanical systems. You can directly convert CAD geometry and assembly constraints into an accurate motion model or create your own motion model from scratch, and the embedded motion solver and robust postprocessing capabilities allow you to study of a broad range of product behaviors.

Multiphysics Sumilation

An uncomfortable truth about modern engineering is that there really are no easy problems left to solve. In order to meet the demands of industry, it’s no longer good enough to do ‘a bit of CFD’ or ‘some stress analysis’. Complex industrial problems require solutions that span a multitude of physical phenomena, which often can only be solved using simulation techniques that cross several engineering disciplines.

Structural Simulation

Understanding how a component or product assembly reacts under stress or vibration is critical in any industry, but as products and materials become increasingly complex, engineers need tools that go beyond linear statics analyses. Simcenter includes the structural solutions you need for a wide range of structural analysis problems within a single user environment. You no longer need one tool for linear statics, another to study fatigue, and yet another for nonlinear analysis. As a result, engineering departments can consolidate analysis tools, and you only need to know a single user interface.